Fractional Distillation of Crude Oil

BR Instrument has specialized in laboratory distillation equipment since 1966. The atmospheric distillation unit ADU and the vacuum distillation unit VDU two crude oil furnaces and a heat.

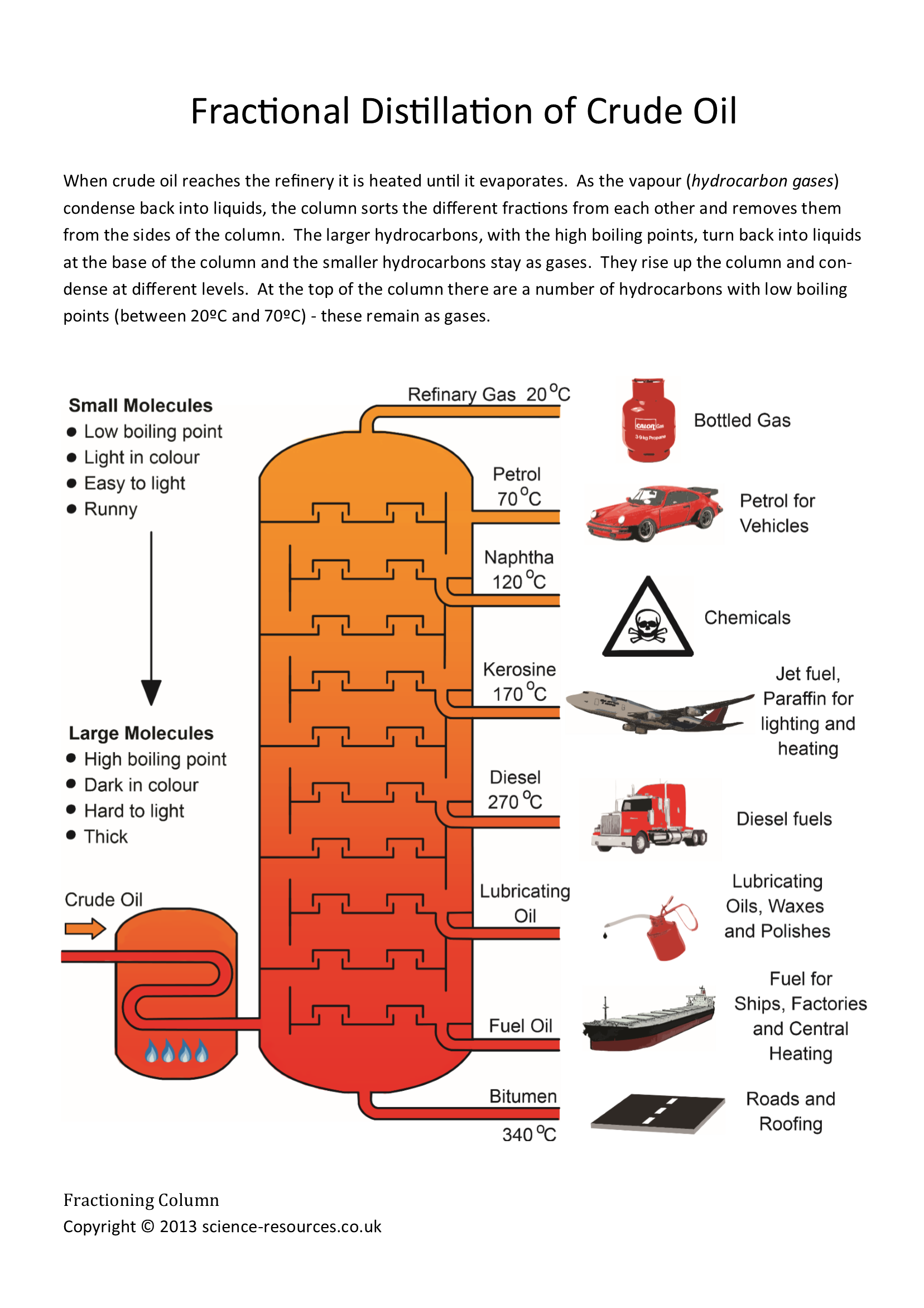

A Diagram Representing The Distillation Of Crude Oil It Shows The Boiling Point Of Each Fraction The Point They Crude Oil Oil And Gas Fractional Distillation

Humans have been using distillation since at least 3000 BC in the Indus valley.

. For crude oil to be used effectively by modern industry it has to be separated into its component parts and have impurities like sulfur removed. After the process our output product is Base oil. Lubricating oil sometimes simply called lubricantlube is a class of oils used to reduce the friction heat and wear between mechanical components that are in contact with each otherLubricating oil is used in motorized vehicles where it is known specifically as motor oil and transmission fluid.

Oil stabilization is an important type of distillation that reduces the vapor pressure of the crude oil enabling safe storage and. The system consists of two crude oil distillation units. The compounds are separated in the.

Crude oil is a naturally occurring liquid that can be refined into various fuels and other petroleum-based products. Heating the mixture of the substances of crude oil liquids with different boiling points to a. Examples of uses of distillation include purification of alcohol desalination crude oil refining and making liquefied gases from air.

Crude oil is a finite resource. Different fractions condense at certain temperature ranges. The fractional distillation of crude oil carries out several steps.

Distillation of Cannabis Oil to make THC distillate and CBD distillate. In fact crude oil futures are the global. Distillation or classical distillation is the process of separating the components or substances from a liquid mixture by using selective boiling and condensation.

The excellent performance of this nanocomposite membrane suggests that novel PVDF modification with polypyrrole had a considerable effect on permeability with high potential for use in the treatment of oily wastewater in the refinery industry. Crude oil drilled from the land or sea is a thick gloopy mixture that contains thousands of different hydrocarbons which have to be separated out before we can use them. Distillation is the process of separating components of a mixture based on different boiling points.

A crude oil distillation plant has many components eg crude oil furnace distillation towers and heat exchangers network. Cracking is used to convert long alkanes into shorter more useful hydrocarbons. When it comes to the fractional distillation of crude oil steamed hot water is used to boil the liquid in order to separate the distillates and because crude oil is a complex liquid there are many distillates that are obtained over a range of temperatures.

An oil refinery or petroleum refinery is an industrial process plant where petroleum crude oil is transformed and refined into useful products such as gasoline petrol diesel fuel asphalt base fuel oils heating oil kerosene liquefied petroleum gas and petroleum naphtha. Petrol and other fuels are produced from it using fractional distillation. 161 illustrates a schematic diagram of the crude oil distillation system considered here.

That happens in an oil refinery through a process called fractional distillation. 75 to 80 of Base Oil Group 1 and 2 with two cuts. Dry distillation is the heating of solid materials to produce gaseous products which may condense into liquids or solids.

Fractional Distillation Organic Chemistry Chemistry FuseSchoolIn this video learn how fractional distillation separates crude oil into useful fraction. The input product for this Waste Lube Oil Plant process includes all kinds of waste or used lube oil. Short path distillation also referred to as fractional distillation produces high-quality cannabis distillate though the process is limited in both scalability and production capacity.

From hot to cold largest hydrocarbons to smallest the. During the short-path process a boiling flask is used to heat crude oil and the oil is agitated with a magnetic stirrer. As the vapor rises it starts to cool down.

Crude oil futures are the most popular and most actively traded energy contract on the commodity market. Gear oil engine oil hydraulic oil etc. The most popular are petrol diesel gas oil or red diesel and kerosene.

It involves several vaporization-condensation steps which takes place in a fractioning column. Fractional distillation is the process used to separate hydrocarbon components in crude oil. As explained above the main difference between fractional and simple distillation is that fractional distillation.

Moreover membrane rejection of crude oil reached about 999. It is through the process of distillation that crude oil transforms into the different fuels and petroleum-based products. Cracking is used to convert long alkanes into shorter more useful hydrocarbons.

Its a more involved version of the distillation you might have used to purify water. Gasoline and many other chemicals are produced from crude oil using fractional distillation. This is used to purify sea water.

This is used in crude oil refining. Fractional distillation is often used to separate mixtures of liquids that have similar boiling points. Petrol and other fuels are produced from it using fractional distillation.

Dry distillation may involve chemical changes such as destructive distillation or cracking and is. Crude oil is a finite resource. The most common method of refining crude is the process of fractional distillation.

This involves heating crude oil to about 350 degrees Celsius to turn it into a mixture of gases. It is processed through fractional distillation to get a wide range of useful products including gasoline diesel aviation fuel heating oil kerosene petroleum naphtha asphalt base. In other words it uses distillation for the fractionation of crude oil.

Common uses of its distillation systems include solvent recycling solvent purification crude oil distillation and many other applications of high efficiency fractional distillation. The vapor then enters a fractional distillation tower. Crude oil is heated until it evaporates.

Petrochemicals feedstock like ethylene and propylene can also be produced directly by cracking crude oil. This method includes the separation of important components according to the difference between their boiling points. The chemicals in a certain fraction are hydrocarbons with comparable numbers of carbon atoms.

There are two basic categories of lubricating oil.

Fractional Distillation Of Crude Oil Poster Science Chemistry Fractional Distillation Distillation Teaching Chemistry

Fractionating Column Fractional Distillation Crude Oil Oils

How Fractional Distillation Of Crude Oil Works Fractional Distillation Oils Crude Oil

Diagram Showing Fractional Distillation Crude Oil Illustration Download A Free Preview Or High Quality Adobe Il Fractional Distillation Distillation Crude Oil

Comments

Post a Comment